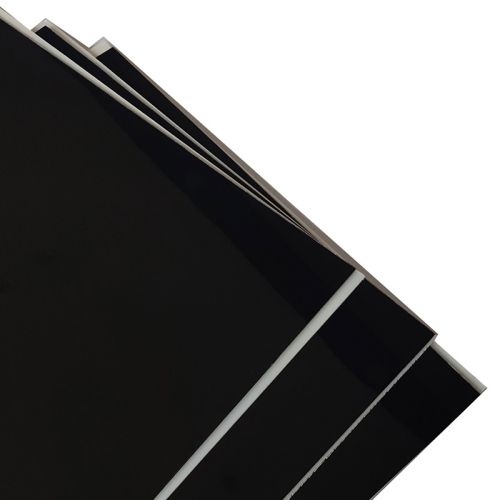

MERIT boasts a team of highly skilled and experienced professionals dedicated to technical development. We offer flexographic printing plates in various thicknesses including 3.94mm, 2.84mm, 2.28mm, 2.0mm, 1.7mm, and 1.14mm. We also offer customized flexo printing plate production to meet the different thickness requirements and unique needs of our customers.

These flexographic printing plates find applications in the printing industry for a wide range of products such as corrugated boxes, flexible packaging, eco-friendly bags, tissue labels, carrier bags, books, and magazines.

Our available flexographic printing plates are as follows:

-

- Solvent Washable Flexo Printing Plates (Analog) Flexographic printing boasts low production cost, flexible combination of process, and the use of water-based ink, making it an environmentally friendly method of printing better than other printing processes such as offset printing and gravure printing.

-

- Solvent Washable Flexo Printing Plates (Digital) Digital flexo printing plate is made by placing plate material directly on a computer-to-plate (CTP) machine, where image data is transferred to a laser that emits a beam to corrode the black film.

-

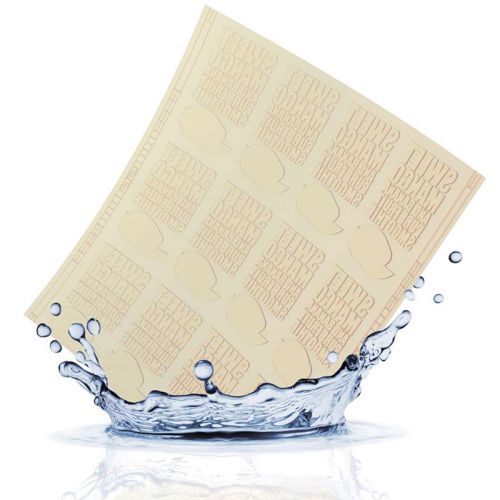

- Water Washable Flexo Printing Plates (Analog & Digital) Analog & digital flexographic printing plates are an advanced type of printing material that offers exceptional print quality, improved production efficiency, and significant cost savings compared to thermal and solvent printing plates.

-

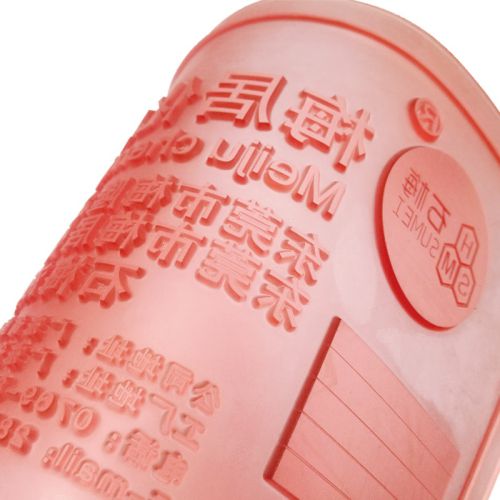

- Liquid Photopolymer Plate MERIT’s liquid photopolymer plates are known for their exceptional durability, high tolerance, and superior ink transfer quality. They’re the ideal choice for printing on corrugated boxes.

Advantages of flexographic printing

- Shorter setup time and cost-effective: Flexographic printing is faster and cheaper than traditional printing methods because it can adjust and replace printing plates more quickly. This saves time and increases productivity.

- Multiple ink and substrate options: Flexographic printing offers a variety of ink and substrate options, so you can print on different materials like paper, plastic film, or aluminum foil to ensure high-quality packaging.

- Flexibility for various business scales: Whether you are a large company or a small studio, flexographic printing can meet your needs. It can handle different printing quantities and frequencies and help you respond to changes in market demand.

- Eco-friendliness: Flexographic printing is environmentally friendly because it uses inks and materials that comply with environmental standards and doesn’t contain harmful substances. It also reduces waste generation, saves energy and resources.