Liquid Photopolymer Plate

Flexographic printing plate

Liquid Photopolymer Plate

Flexographic printing plate

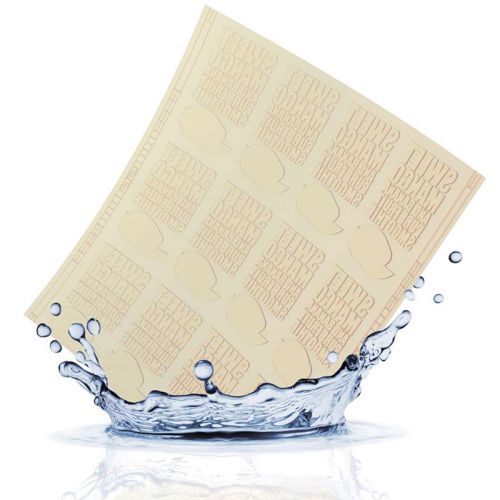

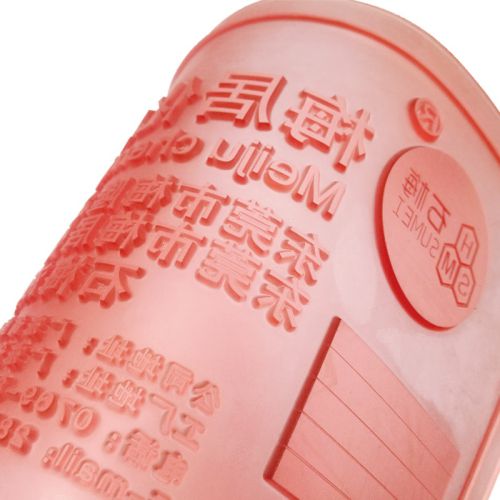

MERIT’s liquid photopolymer plates are known for their exceptional durability, high tolerance, and superior ink transfer quality. They’re the ideal choice for printing on corrugated boxes. At MERIT, we are committed to providing you with environmentally friendly solutions that delivers exceptional printing results.

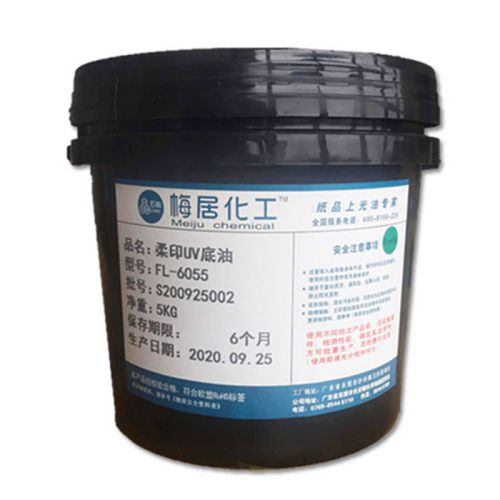

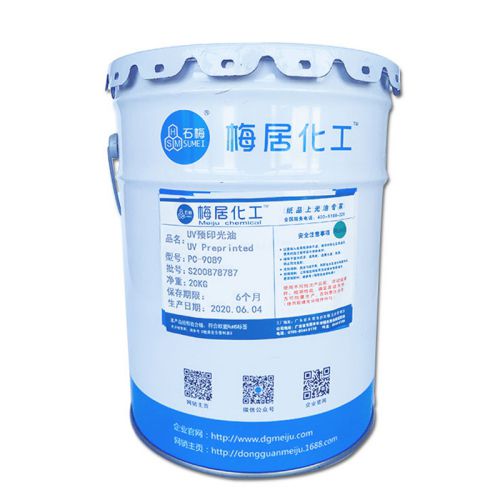

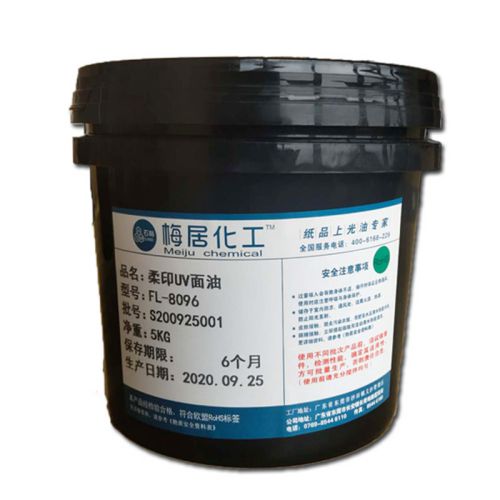

Volume: 18 kg/barrel, 200 kg/barrel